Predictive maintenance: data science for utility companies

Michael Tuijp

Geospatial Data ScientistWhen you think of Geospatial Data Science, you might think of big innovative ideas from forward-thinking dreamers, who sometimes forget for a moment that you have to use data for a practical purpose. Predictive maintenance is an example of an extremely valuable practical application of data science. In this blog, I tell you more about asset management based on predictive insights.

Asset management based on predictions

Efficient asset management benefits from good maintenance predictions. When you manage tens of thousands of assets spread across several provinces and located above, below or on the ground, maintenance without high-level planning is impossible. I can see large filing cabinets in the days when computers did not exist. And vans with maintenance workers who would 'go and see how things were' based on random sampling. I wasn't there, so I don't know for sure. But I can imagine that asset management in 1979 was pretty labour-intensive.

Predictive maintenance was conceived from the idea that there is simply no time or money to send maintenance teams out with a risk of 'false alarm'. In addition, 'outside is inside' is increasingly the aspiration of organisations whose work takes place largely in the outdoors. The time when digital twins display the state of your all your assets in real time has not yet arrived, but the GIS world is moving rapidly in that direction.

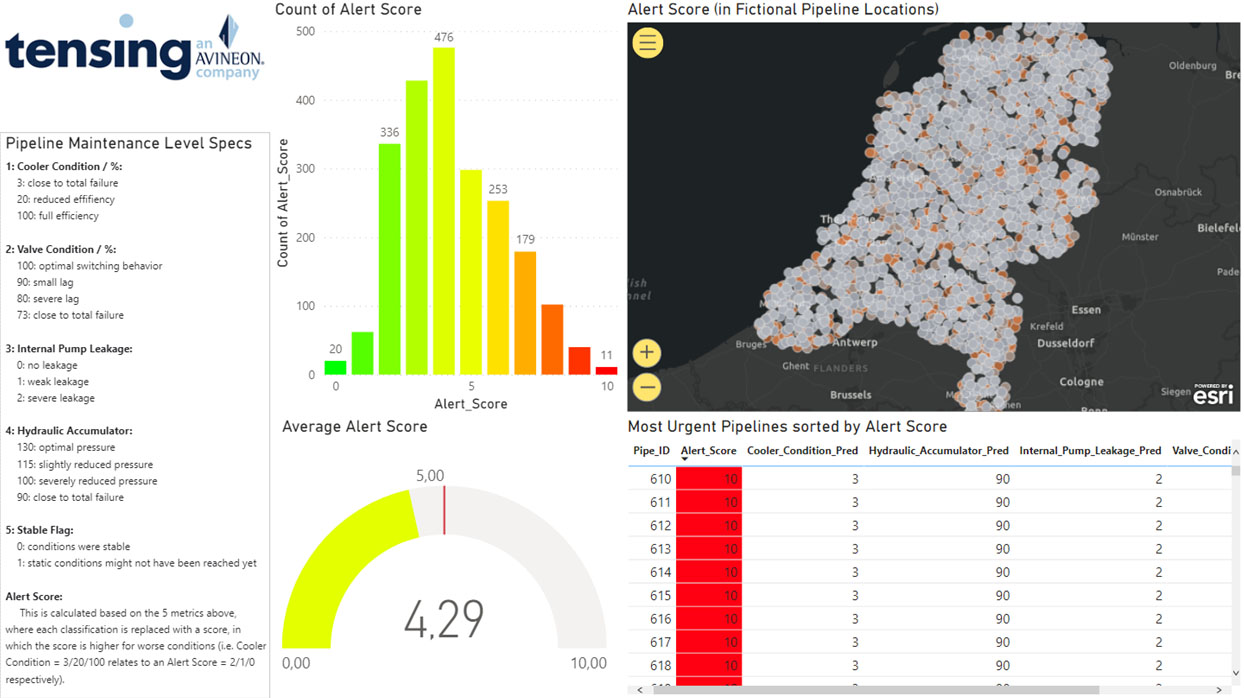

leakage analysis dashboard (fictitious)

Predictive asset management, in other words, or predictive maintenance. I like to make the phenomenon concrete using an example: a dashboard with an alert score that shows the risk of pipeline failure at a glance. So that maintenance crews know where to go first and do not have to determine the highest urgency based on a (partially) subjective assessment.

Image 1: predictive maintenance dashboard for pipeline maintenance. Text continues below the image.

This dashboard is not based on actual data model, but a predictive model. When you set up a dashboard based on actual data, there is a greater risk of being behind the times.

I created this predictive model using PyCaret, a low-code machine learning library that allows you to create sophisticated machine learning workflows. In PyCaret, I created a predictive model for each attribute that provides input to the dashboard. In addition, I set up an email alert for all pipelines that have an excessive Alert Score. So when this is the case, the relevant maintenance team will immediately receive an email with the location of the pipeline.

A common saying in the GIS world is 'a line is a line'. This is also absolutely true when it comes to predictive maintenance. You can also use this dashboard to show the state of power lines, gas pipes or other assets at a glance. Technically, the principle is the same. Tensing is a recognised Esri Utility Network Specialist (an advanced ArcGIS data model for utility, telecom and infrastructure companies, among others). So I am in a luxury position: if I want to know specific things about a particular asset type, I always have a colleague with specific knowledge available.

The value of predictive maintenance is increasing

The number of assets to manage has been increasing for years at almost all our customers in different industries. Due to ongoing construction the number of assets and also the total amount of asset data is constantly increasing. In addition, the labour market remains tight and therefore organisations are constantly looking for ways to do more work with smaller departments.

And then there is the impact of climate change. Municipalities, provinces, the state, utilities: they are all innovating to contribute to a sustainable world. In addition, climate change also has a direct impact on the lifespan of assets.

Image 2: Asphalt maintenance can vary from country to country or even area to area. Text continues below the image.

Let's take asphalt as an example. The composition of asphalt is different in the Middle East than it is in Lapland, as different weather conditions call for different production and maintenance methods. I can so imagine (I'm a Geospatial Data Scientist, not a road engineer, I'll add) that these kinds of additional factors drive the demand for smart data use even further.

Strategic Market Research, a US market research firm, concludes that the total market value of predictive maintenance of industrial machinery in the US is going to grow from $4.32 trillion to $45.75 trillion between 2021 and 2030. So if the relative growth in the market value for predictive maintenance of assets is even a fraction of these figures, we are already talking about a small revolution.

The world is becoming increasingly complex and crowded. I am certain that predictive maintenance is currently still in its infancy and that organisations have a lot to gain in this area. Interested in exploring the possibilities of predictive maintenance? Feel free to contact me!

.png)